The Problem with Plastic Straws

Plastic straws have become a worldwide environmental concern. These small, seemingly harmless items have quickly become one of the most significant sources of pollution in our oceans and landfills. The durability and long decomposition time of plastic straws have contributed to their negative impact on the environment. It is estimated that in the United States alone, over 500 million plastic straws are used and discarded daily. To combat this problem, alternative materials have emerged, including PLA, a sustainable and eco-friendly material.

PLA---A Sustainable Alternative

PLA, which stands for polylactic acid, is a thermoplastic polyester derived from renewable resources, such as corn starch or sugarcane. Unlike traditional plastic straws made from petroleum, PLA straws are biodegradable and compostable. This environmentally friendly material has gained popularity due to its potential to reduce carbon emissions and plastic waste. PLA straws offer a sustainable solution to minimize the negative impact of plastic straws on our environment.

The Engineering Process of PLA Straws

So, how exactly are PLA straws made? The engineering process involves several steps to transform renewable resources into functional straws. First, the raw material, such as corn starch or sugarcane, is harvested and processed to extract the necessary components for PLA production. These components are then fermented and refined to create lactic acid.

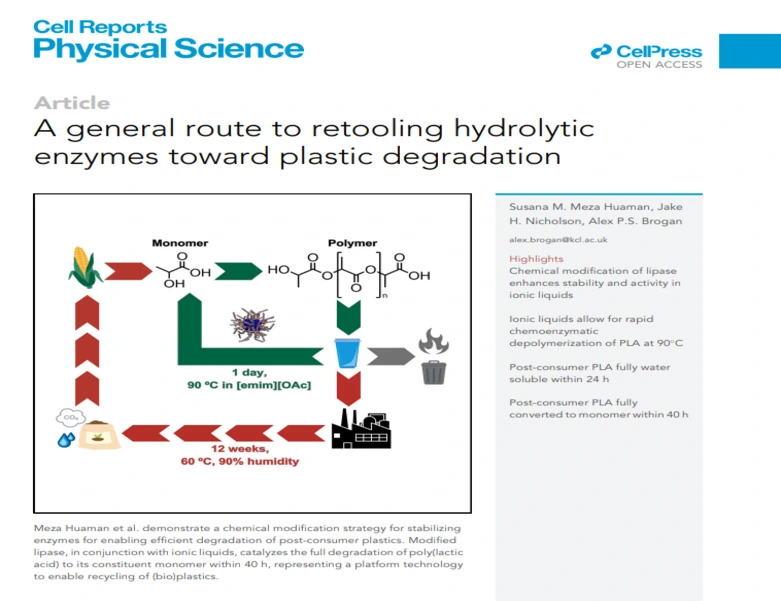

Once lactic acid is obtained, it undergoes a process called polymerization. In this step, the lactic acid molecules are linked together to form long chains, resulting in the creation of polylactic acid. The polylactic acid is then converted into resin pellets, which can be further processed to produce various PLA products, including straws.

To manufacture PLA straws, the resin pellets are melted and extruded through a die to achieve the desired straw shape and size. The extrusion process involves heating the resin pellets to a specific temperature, which allows them to become pliable. The molten PLA is then forced through a shaped opening, forming a continuous tube. As the tube cools down, it solidifies, and the final PLA straw is cut into individual pieces.

Embracing PLA Straws: A Step Towards Environmental Harmony

PLA straws provide us with an opportunity to make a positive impact on our environment. By choosing PLA straws over traditional plastic ones, we actively reduce our carbon footprint and contribute to the reduction of plastic waste. Furthermore, since PLA straws are compostable, they can be disposed of in an eco-friendly manner, either through industrial composting facilities or backyard composts.

The adoption of PLA straws extends beyond individual responsibility. Businesses and organizations also play a crucial role in transitioning to sustainable alternatives. Encouraging the use of PLA straws in restaurants, cafes, and other establishments can significantly reduce the consumption of petroleum-based plastic straws. Additionally, supporting companies that produce and supply PLA straws helps to drive the demand for eco-friendly alternatives and promote a more sustainable future.

As consumers, we have the power to make choices that align with our commitment to environmental harmony. By understanding the engineering process behind PLA straws and recognizing their importance in reducing plastic pollution, we can actively contribute to a healthier planet. Let's embrace PLA straws and inspire others to join us in this movement towards a more sustainable and responsible future. Together, we can make a difference.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский português

português العربية

العربية ไทย

ไทย Malay

Malay