How is Polylactic Acid (PLA) made? Polylactic Acid (PLA) Products are made?

The basic steps for producing Polylactic Acid (PLA) from corn are as follows: 1. First, corn starch must be converted into sugars through a mechanical process called wet milling. Wet milling separates the starch from the germ. Once these components are separated, either acid or enzymes are added. They are then heated to convert the starch into glucose. 2. Next, ferment the glucose. One of the most common fermentation methods is to add lactic acid bacteria to the glucose. This, in turn, creates lactic acid. 3. Lactic acid is then converted into lactide, a cyclic dimer of lactic acid. These lactide molecules bind together to form a polymer. 4. The result of this polymerization is small raw materials Polylactic Acid (PLA), which can then be transformed into a range of Polylactic Acid (PLA) plastic products.

What are the Benefits of Polylactic Acid (PLA) Products?

Compared to traditional petroleum-based plastics, Polylactic Acid (PLA) Plastics require 65% less energy to produce. They also reduce greenhouse gas emissions by 68%.

Environmental Benefits:

Compared to PET plastic, over 95% of plastics worldwide are made from natural gas or crude oil. Fossil fuel-based plastics are not only harmful, but they are also finite resources. Polylactic acid (PLA) products offer functional, renewable, and comparable alternatives.

Bio-based:

The materials used in bio-based products come from renewable agriculture or plants. Because all PLA products are derived from sugar starch, PLA is considered bio-based.

Biodegradable:

PLA products meet international standards for biodegradability, naturally breaking down instead of accumulating in landfills. It does require certain conditions to degrade quickly. In industrial composting facilities, it can decompose within 45 to 90 days.

Non-toxic Smoke Emissions:

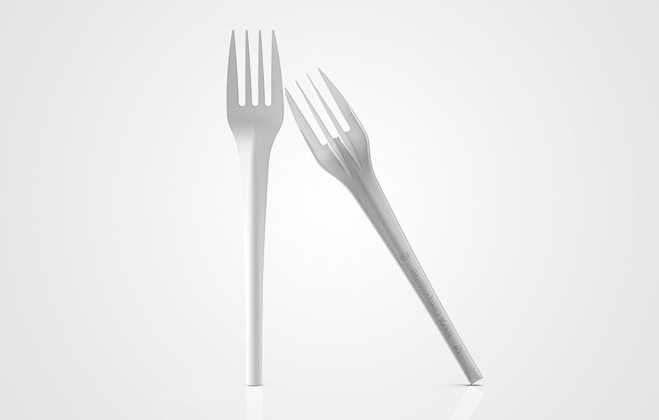

Unlike other plastics, bio-plastics do not emit any toxic smoke when incinerated. PLA plastic is a thermoplastic, so when heated to its melting temperature, it becomes malleable and stretchable. It can solidify and be molded into various forms, making it an excellent choice for food packaging and 3D printing. PLA has been approved by the FDA as a Generally Recognized as Safe (GRAS) polymer and can be safely used for food contact.

Benefits of PLA Products for Food Packaging

PLA products have different harmful chemical compositions compared to petroleum-based products. They are as sturdy as many traditional plastics, safe for freezing, and cups can withstand temperatures up to 110°F (PLA products can withstand temperatures up to 200°F). PLA products are non-toxic, carbon-neutral, and 100% renewable. In the past, when foodservice operators wanted to switch to environmentally friendly packaging, they may have only found expensive and inferior products. However, PLA offers functionality, cost-effectiveness, and sustainability. Switching to these products is an important step in reducing the carbon footprint of food businesses.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский português

português العربية

العربية ไทย

ไทย Malay

Malay